Fermentation‐ top and bottom- Fermentation is the process by which yeast converts sugars into alcohol and carbon dioxide. There are two main types of fermentation in brewing: top fermentation and bottom fermentation.

Top Fermentation

- Top fermentation uses yeast strains that tend to rise to the top of the fermenting liquid.Opens in a new windowmidtfyns-bryghus.dk Top fermentation beer

- These yeasts typically work at warmer temperatures (between 60 and 75 degrees Fahrenheit).

- Top-fermented beers are known for their fruitier and spicier flavors, as well as their higher levels of esters and phenols.

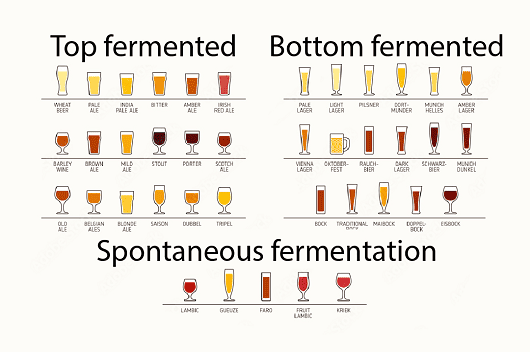

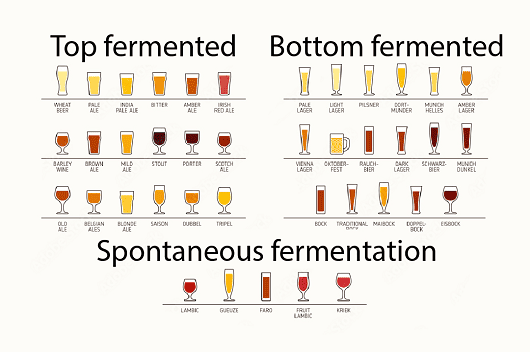

- Common examples of top-fermented beers include ales, IPAs, stouts, porters, and wheat beers.

Bottom Fermentation

- Bottom fermentation uses yeast strains that settle at the bottom of the fermentation tank.Opens in a new windowwww.micetgroup.com Bottom fermentation beer

- These yeasts prefer cooler temperatures (between 42 and 54 degrees Fahrenheit).

- Bottom-fermented beers are known for their smoother, cleaner, and more crisp flavors.

- Common examples of bottom-fermented beers include lagers, pilsners, and helles.

What is Required Fermentation‐ top and bottom

Both top and bottom fermentation require some basic ingredients and conditions, but they differ in terms of temperature and yeast strain:

Ingredients (Common to Both):

- Wort: This is the sugary liquid extracted from malted grains, the base for both ales and lagers.

- Yeast: The key player that converts sugars to alcohol and CO2. The strain is what differentiates top and bottom fermentation.

- Water: Makes up the majority of the final beverage.

- (Optional) Hops: Adds bitterness, aroma, and acts as a natural preservative.

Conditions:

- Sanitation: A clean environment is crucial to prevent unwanted bacteria from spoiling the brew.

Key Differences:

Temperature:

- Top Fermentation: Warmer temperatures, typically between 60-75°F (15-24°C). This allows the yeast to work faster, often leading to shorter fermentation times (around a week or more).

- Bottom Fermentation: Cooler temperatures, typically between 42-54°F (5-12°C). This slower pace creates a smoother flavor profile but requires longer fermentation times (often weeks or even months).

Yeast Strain:

- Top Fermentation: Uses yeast strains that thrive in warmer environments and tend to float to the surface during fermentation. These yeasts produce more esters and phenols, contributing to fruitier and spicier flavors in the final beer.

- Bottom Fermentation: Uses yeast strains that prefer cooler temperatures and flocculate (clump together and settle) at the bottom of the fermentation tank. These yeasts produce a cleaner flavor profile with less emphasis on esters and phenols.

Who is Required Fermentation‐ top and bottom

There isn’t a specific person required for top and bottom fermentation. The key ingredient for both is the yeast strain.

- Top Fermentation: This type uses yeast strains like Saccharomyces cerevisiae. These yeasts work best at warmer temperatures.

- Bottom Fermentation: This type uses yeast strains like Saccharomyces pastorianus (a descendant of S. cerevisiae). These yeasts prefer cooler temperatures.

While a brewer may choose a specific yeast strain for a desired beer style, the fermentation process itself doesn’t require any human intervention beyond setting the temperature and providing a clean environment. The yeast does the hard work of converting sugars to alcohol and CO2.

When is Required Fermentation‐ top and bottom

Top and bottom fermentation aren’t necessarily “required” in the sense that they’re mandatory steps. Fermentation itself is the essential process for creating beer, and both top and bottom fermentation are simply different methods using different yeast strains at different temperatures.

Here’s a breakdown:

- Fermentation is Required: This process is crucial for turning wort (sugary liquid from malted grains) into beer. Yeast consumes the sugars in the wort, producing alcohol and carbon dioxide as byproducts. Without fermentation, you wouldn’t have beer, just sweet wort.

- Top or Bottom Fermentation is a Choice: The brewer decides which method to use based on the desired beer style. Top fermentation creates beers with bolder flavors and aromas, while bottom fermentation produces smoother, cleaner-tasting beers.

Here’s an analogy: Think of fermentation like cooking. Cooking food is essential, but there are many ways to cook (boiling, frying, baking). Top and bottom fermentation are like different cooking methods used to achieve different results.

Where is Required Fermentation‐ top and bottom

Top and bottom fermentation don’t have a specific required location. They can happen in any clean and controlled environment where the brewer can maintain the desired temperature. Here’s why location isn’t a key factor:

- Focus on Conditions: Both methods require a sealed container (fermenter) to trap the CO2 produced by the yeast. The key is maintaining the right temperature for the chosen yeast strain.

- Modern Brewing: Modern breweries typically have dedicated fermentation rooms with temperature control systems. These rooms can house multiple fermenters for different beers.

- Homebrewing: Homebrewers can use various methods to control fermentation temperature. Some use temperature-controlled chambers, while others may use simpler methods like ice baths or placing the fermenter in a specific location based on ambient temperature.

Essentially, the location doesn’t matter as much as having the ability to maintain the ideal temperature range for the chosen yeast strain.

How is Required Fermentation‐ top and bottom

There seems to be a misunderstanding. Fermentation itself, the process of yeast converting sugars to alcohol and CO2, is required to make beer. It’s not optional. Top and bottom fermentation are simply two different methods of fermentation that differ in:

- Yeast strain: Top fermentation uses strains like Saccharomyces cerevisiae that thrive in warmer temperatures (60-75°F) and tend to rise to the surface. Bottom fermentation uses strains like Saccharomyces pastorianus that prefer cooler temperatures (42-54°F) and settle at the bottom.

- Temperature: Top fermentation is faster due to the warmer temperatures, while bottom fermentation takes longer due to the cooler temperatures.

- Flavor profile: Top fermentation produces beers with more esters and phenols, leading to fruitier and spicier flavors. Bottom fermentation creates a cleaner, smoother taste.

Here’s a breakdown to clarify:

Required:

- Fermentation: This process is essential for converting wort (sugary liquid from grains) into beer. You cannot make beer without fermentation.

Choices:

- Top or Bottom Fermentation: The brewer chooses the method based on the desired beer style. They can achieve a wider range of flavors with top fermentation, while bottom fermentation produces a crisper, cleaner taste.

Location doesn’t significantly impact these methods. As long as the brewer can maintain the right temperature for the chosen yeast strain in a clean and sealed container (fermenter), top or bottom fermentation can occur anywhere.

Case Study on Fermentation‐ top and bottom

Top vs. Bottom Fermentation in Craft Beer Production

Introduction:

This case study examines the impact of top and bottom fermentation on two distinct craft beer styles: American Pale Ale (APA) and German Pilsner. It will explore the differences in yeast strains, fermentation temperatures, and resulting flavor profiles.

Beers:

- American Pale Ale (APA): A top-fermented beer known for its hoppy bitterness, citrusy aromas, and moderate alcohol content (around 5%).

- German Pilsner: A bottom-fermented beer characterized by a light body, crisp finish, and prominent malt character with subtle bitterness (around 5% alcohol).

Yeast Strains:

- APA: Utilizes top-fermenting yeast strains like Saccharomyces cerevisiae, which thrive at warmer temperatures (60-75°F). These yeasts produce higher levels of esters and phenols, contributing to the fruity and spicy notes in APAs.

- Pilsner: Employs bottom-fermenting yeast strains like Saccharomyces pastorianus, which prefer cooler temperatures (42-54°F). These yeasts produce a cleaner flavor profile with minimal esters and phenols.

Fermentation:

- APA: Due to the warmer temperatures, top fermentation for an APA is typically faster, taking around a week or more.

- Pilsner: Bottom fermentation requires cooler temperatures, resulting in a longer fermentation process, often lasting several weeks or even months. This extended lagering period allows the yeast to clean up byproducts and contributes to the smooth taste of Pilsners.

Flavor Profile:

- APA: The combination of top fermentation and a warm environment leads to a more pronounced hop character, with citrusy and floral notes from the hops complementing the fruity esters produced by the yeast.

- Pilsner: Cooler temperatures and a cleaner yeast strain result in a Pilsner with a delicate balance between malt sweetness, subtle bitterness, and a crisp finish.

Impact on Brewing Process:

- Top fermentation: Requires less specialized equipment compared to bottom fermentation due to the warmer temperatures. However, temperature control is still essential to maintain consistent results.

- Bottom fermentation: Often necessitates dedicated fermentation chambers with precise temperature control systems for optimal results. This can add complexity and cost to the brewing process.

Conclusion:

Top and bottom fermentation are distinct approaches that significantly influence the final product. Choosing the right method is crucial for achieving the desired beer style. Top fermentation allows brewers to experiment with bolder flavors and aromas, while bottom fermentation results in cleaner, more delicate taste profiles. Understanding these differences empowers brewers to craft unique and diverse beers.

White paper on Fermentation‐ top and bottom

Unveiling the Secrets of Top and Bottom Fermentation

Abstract

Fermentation is the cornerstone of brewing, transforming sugary wort into the beloved beverages we know as beer. However, within this essential process lie two distinct methods: top and bottom fermentation. This white paper delves into the science behind these techniques, exploring the yeast strains, temperature control, and their impact on the final flavor profile. Through case studies and practical applications, brewers of all levels can gain valuable insights into crafting unique beers using top and bottom fermentation.

Introduction

For centuries, brewers have harnessed the power of fermentation to create a vast array of beers. At the heart of this process lies the humble yeast, a microscopic organism that converts sugars into alcohol and carbon dioxide. However, the specific type of yeast and the fermentation temperature significantly impact the resulting beer style. This white paper explores the fascinating world of top and bottom fermentation, guiding brewers towards achieving their desired flavor profiles.

Top Fermentation: A Celebration of Bold Flavors

Top fermentation utilizes yeast strains, such as Saccharomyces cerevisiae, that thrive in warmer temperatures (60-75°F). These yeasts have a faster fermentation cycle, often completing within a week or more. However, their magic lies in the production of esters and phenols. These byproducts contribute a spectrum of fruity, spicy, and floral aromas, adding complexity to the final beer.

Iconic Top-Fermented Styles:

- American Pale Ale (APA): Known for its hoppy bitterness, citrusy notes, and moderate alcohol content, APAs are a testament to the versatility of top fermentation.

- Wheat Beer: The signature banana and clove character of wheat beers is a direct result of top-fermenting yeasts and their unique flavor profile.

- Stout and Porter: These darker styles often showcase the rich, roasted malt character alongside hints of chocolate and coffee, further amplified by top fermentation.

Bottom Fermentation: A Journey Towards Crispness

Bottom fermentation employs yeast strains like Saccharomyces pastorianus, which prefer cooler temperatures (42-54°F). These yeasts flocculate (clump together) and settle at the bottom of the fermentation tank. The cooler temperatures lead to a slower fermentation process, often lasting several weeks or even months. This extended lagering period allows the yeast to clean up byproducts, resulting in a smoother, cleaner flavor profile.

Classic Bottom-Fermented Styles:

- Pilsner: This iconic style embodies the essence of bottom fermentation. Its light body, crisp finish, and subtle bitterness are a testament to the delicate balance achieved through this method.

- Lager: A broad category encompassing various styles, lagers typically showcase a clean malt character with minimal hop bitterness, thanks to bottom fermentation.

- Helles: This German style is known for its pale color, balanced malt sweetness, and a hint of noble hops, all achieved through precise bottom fermentation techniques.

Case Study: Unveiling the IPA Divide

India Pale Ale (IPA) is a popular style, but brewers can achieve it using both top and bottom fermentation. Top-fermented IPAs tend to be more expressive, showcasing bolder hop character and fruity esters. Conversely, bottom-fermented IPAs offer a cleaner, more malt-driven experience with the hops taking center stage in terms of bitterness. This case study highlights how fermentation method plays a crucial role in shaping even within a single beer style.

Practical Applications: Mastering Fermentation Techniques

For top fermentation, maintaining a consistent warm environment is essential. Brewers can utilize a fermentation chamber or simpler methods like temperature-controlled rooms or wrapping the fermenter with a heating pad. Bottom fermentation necessitates more precise temperature control, often requiring dedicated chambers with cooling systems. Regardless of the method, proper sanitation remains paramount throughout the process.

Conclusion

Top and bottom fermentation are not merely technical terms; they represent distinct pathways to creating unique and flavorful beers. This white paper has equipped brewers with the knowledge to explore the impact of yeast strains and temperature on the final product. By understanding these techniques, brewers can confidently embark on a journey of crafting diverse and exceptional beers, each a testament to the fascinating world of fermentation.

Further Considerations:

- This white paper can be expanded to include information on selecting the right yeast strain for a specific beer style.

- Additional case studies could explore the impact of fermentation on other beer styles.

- The paper could delve into the challenges and considerations of scaling up fermentation from homebrew to commercial production.

By incorporating these elements, you can create a comprehensive resource that empowers brewers of all levels to unlock the full potential of top and bottom fermentation.

Industrial Application of Fermentation‐ top and bottom

Fermentation, both top and bottom, plays a vital role in the industrial production of beer. While the basic principles remain the same, these methods have distinct advantages for large-scale brewing:

Top Fermentation:

- Faster turnaround times: Top-fermented beers generally require shorter fermentation periods (a week or more) compared to bottom-fermented styles. This allows breweries to produce more beer in a shorter timeframe, increasing efficiency and output.

- Wider variety of styles: Top fermentation offers brewers more flexibility in terms of flavor profiles. The higher ester and phenol production leads to beers with bolder, fruitier, and spicier characteristics, catering to diverse consumer preferences.

- Lower energy consumption: Since top fermentation utilizes warmer temperatures, breweries require less energy for temperature control compared to bottom fermentation. This can be a significant advantage in terms of production costs.

Examples of industrially produced top-fermented beers:

- American Pale Ales (APAs)

- India Pale Ales (IPAs) (including some variations)

- Stouts and Porters

- Wheat Beers

- Saisons

Bottom Fermentation:

- Consistent quality: Bottom fermentation’s cooler temperatures and longer fermentation periods (weeks or months) allow for more controlled and consistent flavor profiles. This is crucial for large-scale production where maintaining brand consistency is paramount.

- Cleaner, crisper taste: The extended lagering period in bottom fermentation allows the yeast to clean up byproducts, resulting in a smoother and crisper final product. This is ideal for popular styles like Pilsners and Lagers.

- Longer shelf life: Bottom-fermented beers tend to have a longer shelf life due to the lower levels of esters and phenols. This is advantageous for large breweries that need their products to remain stable during transportation and storage.

Examples of industrially produced bottom-fermented beers:

- Pilsners

- Lagers (various styles)

- Helles

- Bocks

Challenges and Considerations:

- Capital investment: Bottom fermentation often necessitates dedicated fermentation chambers with precise temperature control systems. This can be a significant upfront investment for breweries.

- Longer production cycles: While bottom fermentation produces consistent results, the extended fermentation times can lead to longer production cycles compared to top fermentation.

- Yeast management: Maintaining a healthy and pure yeast culture is crucial for both methods, but it becomes especially important in large-scale bottom fermentation due to the longer fermentation periods.

Conclusion:

Top and bottom fermentation are essential tools for industrial beer production, each offering distinct advantages. Breweries choose the method that best suits their desired styles, production efficiency, and target market. Understanding these methods allows them to create a wide range of beers that cater to diverse consumer preferences.